The Decklite Working Platform is a substitute to scaffolding.

Decklite™ is easy and fast to deploy, thereby reducing risk exposure (erection man hours) and increasing efficiency. In addition, Decklite™ offers the same safe access for the maintenance crews as traditional scaffolding.

The Decklite™ Patented System is the future technology to access difficult to reach areas efficiently.

The Decklite™ Working Platform is tensioned to form a substantially flat deck surface, which provides workers safe, easy, quick access to complete job requirements.

Decklite™ is a safe option for use whilst plant is operational.

Decklite™ has been trialled and proven offshore, and has been approved for the Oil & Gas Industry for Health, Safety & Environmental requirements for all maintenance and inspection works.

Access by Decklite™ in terms of efficiency far outweighs the significant time to erect and dismantle scaffold. Decklite™ is the ideal alternative to scaffolding methods, and has particular benefits in cost, safety and efficiency for accessing areas quickly.

Compared to conventional access methods, Decklite has the added advantages over cost/time/resources (CTR), i.e. cost effective and gives more uptime to operations and productivity.

The Deckroom Hotwork Enclosure can be used for Hotwork alone or be utilized with the Decklite Working Platform as a Decklite Safety Accessory (DSA) when Hotwork is to be carried out.

Deckroom™ is also very suitable for protection against exposure in extremely cold weather conditions.

It is a quality pressurized enclosure with controlled air flow and has an automatic shutdown gas detector to ensure safety when carrying out Hotwork on a hydrocarbons facility.

Deckroom™ is manufactured from the highest grade flame retarded materials.

Electric Arc Welding, Oxy-acetylene Cutting, Grinding, Blasting or chipping hand tool, use of non-intrinsically safe electrical test equipment. Any source of open flame, spark or incandescent materials may be classed as Hotwork.

As protection from exposure in extremely cold conditions.

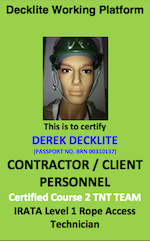

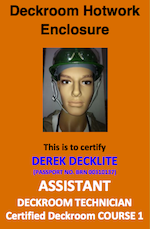

Decklite Access provide thorough training to personnel for use of the Decklite Working Platform and Deckroom Hotwork Enclosure as required under HSE Guidelines. The training is conducted by Decklite approved Training Facilities.

Depending on the level of qualification required of specific personnel, the courses are available as follows;

| Course No. | Description | Certificate |

|---|---|---|

| Course 1 |

Decklite Familiarization & Safety Induction

A one day course of familiarization to access the DWP such as double hook up harness, Working at Height regulations and safety induction to carry out work on the DWP without a Rope Access Certificate. Contractor and/or Client Personnel Onsite Decklite Familiarization & Safety InductionA brief on site induction for visitors who require access to the DWP (Decklite Working Platform) such as inspectors and management an onsite course can be conducted by a Decklite Supervisor (Course 3 Certified) and carried out at the job site. The personnel shall be supervised at all times whilst accessing the DWP by the Decklite Supervisor. Attendees / Candidates:Inspectors, management, visitors. |

|

| Course 2 |

TNT Team – Multi Skilled Access To carry out work whilst utilizing rope access skills. Install, Maintain, Dismantle the DWP (Decklite Working Platform) & carry out skills of trade on the DWP. Install, Maintain, and Dismantle the DSA (Decklite Safety Accessories). To assist with the Deckroom Hotwork Enclosure. Attendees / Candidates:Certified Level 1 IRATA Rope Access | What is the Decklite TNT Team?TNT stands for Towards New Technology. The TNT Team comprises of Multi-skilled personnel from both Decklite and Client contractors or subcontractors. The Decklite TNT Team shall be made up of:

The instigation and utilization of the Team shall:

|

|

| Course 3 |

Decklite Supervisor / Qualified Decklite Level 3 Technician Supervisor – Full knowledge of the DWP HSE Guidelines & Checklists. DWP installation, Maintain, Dismantle whilst using ropes. Head of personnel / supervisor under the Decklite License Agreement Attendees / Candidates:Certified Level 3 IRATA Rope Access |

|

| Course No. | Description | Certificate |

|---|---|---|

| Course 1 |

Assistance Deckroom Hotwork Enclosure Install, Maintain, Dismantle, Monitor the Deckroom Hotwork Enclosure. Scaffolding Experience |

|

| Course 2 |

Advanced Deckroom Hotwork Enclosure Install, Maintain, Dismantle, Monitor the Deckroom Hotwork Enclosure. Advanced Scaffolder |

|